RFM-102S

Reform’s Stick Pack Machine for Liquid & Paste Products is the perfect packaging solution to pack your liquid or paste products in stick shaped pouches.

Stick Pack Machine For Liquid & Paste Products:

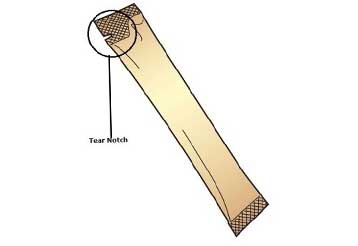

RFM-102S is a fully automatic packaging machine, designed to pack liquid and paste products such as olive oil, salad dressing, ketchup, mayonnaise, mustard, honey, disinfectant…etc. With a high speed, performance and precision which is insured by the liquid filling system driven by a Servomotor. The Stick Pack Machine for Liquid and Paste Products does the forming, the filling, and the sealing in Stick Packs (three sides sealed one on the top, one on the bottom and a transversal one). The speed of the machine varies between 40 and 300 Stick/min, this variation linked to the viscosity of the product, the weight, and the number of lanes.| RFM-102S TECHNICAL SPECIFICATIONS: | |

| Weight Range | 1 – 100 GR (Adjustable) |

| Sachet Width | 16 – 90 mm (Prefixed) |

| Sachet Length | 40 – 200 mm (Adjustable) |

| Number of Lines | 2 – 3 – 4 – 5 – 6 and 8 Lanes |

| Speed | Min: 40 – 100 stick/min – Max : 160 – 600 Stick/min |

| Applications | Suitable for packing liquid and paste products such as olive oil, vinegar, salad dressings, ketchup, mayonnaise, mustard, honey…etc |

All the specifications of the machine depend on the product, the filling quantity, and the packaging material quality.

Why you should choose Reform’s Stick Pack Machine For Liquids:

»Reform's stick pack machines for liquids are manufactured under the European standards (CE certificated), and the international standards (ISO9001 certificated) that obligate the manufacturer to keep providing products that satisfy the customer, while respecting the regulatory requirement.

»Availability of spare parts

»An after sales service that is always ready to provide all the support needed.

»A 2 years guarantee is offered that covers all electric, pneumatic, and mechanic parts.

»Every machine is equipped by SIEMENS PLC control system and 7 inch colored touch screen.

»The body of the machine is made from stainless steel SS304, and the internal parts that have contact with the product are made from stainless steel SS316.

»All Reform’s machines have been designed to run 24/7.

»Reform’s machines give perfect results with low consumption of Energy and Air.

»Low maintenance and low operating cost.

Manipulation of the machine:

»RFM-102S is fully automatic packaging machine, and its function based on two systems: Pneumatic and Mechanic, which make the manipulation of the machine quiet simple.

»One operator can run the machine.

»All the settings of the machine (bag length, weight, sealing heat time, and speed), can be changed easily from the freindly touch screen.

Installation Of The Machine:

»Reform provides the installation of the machine and a free training. When the machine arrive to the client site, and after preparing the electricity and air compressor needed to run the machine, we will send a technician to install the machine, and give a free training on how to run the machine.

»Generally, the process takes two to three days.

What Is The Price Of The Stick Pack Machine For liquid andPpaste Products?

»The price of the stick pack machine for liquids depends on the number of lines, the options added to the machine, so the more your machine is customized the more you expect to pay.

+90 530 309 99 58

sales@reformmak.com